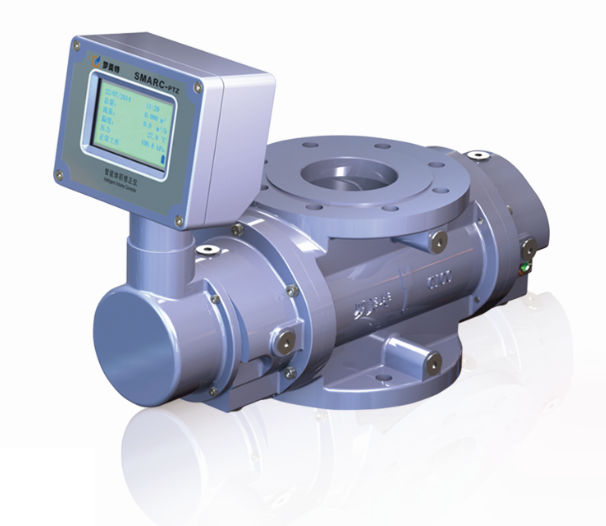

The MTRM Series Roots flowmeter is a wide range and high precision flowmeter, which designed and developed by ourselves on the basis of absorbing the advantages of imported products. The product integrates the functions of machinery, termperature and pressure correction, remote transmission, recharge,valve control into one assembly. The product is mainly used in gas metering for industrial and commercial users.The product is exquisite and beautiful in appearance, whose performance is leading position in the industry, with a variety of specification.

The product’s mechanical performance is stable. Range ratio can reach 1:300. Initial flow rate is 0.04m³/h. Intergrated Mechanica counting, Temperature and Pressure correction, Remote transmission, Recharge, Valve control into one assembly. Integrated circuit and low efficiency design. The battary life can last more than 3 years, and the memery can store data for 12 months ( a set of data per hour). The meter head can rotate freely and easy to reading data

Specificati

Flow Rang

Flange OD

Pressure Loss

Flange Distance

Length

m3/h

mm

kPa

mm

mm

MTRM40A(Z)

0.32-16

DN40

0.1

171

438

MTRM40B(Z)

0.5-25

DN40

0.1

171

438

MTRM40C(Z)

0.5-40

DN40

0.1

171

463

MTRM50A(Z)

0.65-65

DN50

0.15

171

489

MTRM50B(Z)

0.67-100

DN50

0.24

171

545

MTRM80A(Z)

0.8-160

DN80

0.26

171

582

MTRM100A(Z)

1.25-250

DN100

0.32

241

575

MTRM100B(Z)

2-400

DN100

0.53

241

653

MTRM100C(Z)

3.25-650

DN100

0.75

271

744

MTRM150A(Z)

3.5-700

DN150

0.76

406

804

MTRM150B(Z)

5-1000

DN150

0.77

406

920

MTRM200A(Z)

8-1600

DN200

0.78

406

1020

Remarks : 1. Nominal pressur: PN1.6Mpa, standard pressure sensor 0.5Mpa, any special requirement need to send new request when send orders.

2. All products is according to the requirement of grade 1.5, 1.0

3. Smart roots flowmeter’s specification has the lettle “Z” and Mechanical flowmeter has no lettle “Z”.型号

规格

流量

规格

通径

DN

(mm)

A

A1

H1

H

B

D

K

n

d

一字双显

机械

双显

一字双显

机械

双显

双显

机械

一体

MTRM-40A

G10

DN40

438

326

142

112

325

140

155

150

110

4

M16×40

MTRM-40B

G16

DN40

438

326

142

112

325

140

155

150

110

4

M16×40

MTRM-40C

G25

DN40

463

351

155

125

325

140

155

150

110

4

M16×40

MTRM-50A

G40

DN50

489

381

170

141

345

171

165

165

125

4

M16×45

MTRM-50B

G65

DN50

545

437

198

169

345

171

165

165

125

4

M16×45

MTRM-80A

G100

DN80

582

474

216

187

345

171

165

200

160

8

M16×45

MTRM-100A

G160

DN100

575

468

214

181

418

241

252

220

180

8

M16×50

MTRM-100B

G250

DN100

653

546

253

220

418

241

252

220

180

8

M16×50

MTRM-100C

G400

DN100

744

637

309

276

418

241

252

220

180

8

M16×50

MTRM-150A

G400

DN150

804

692

304

280

532

406

432

285

240

8

M20×65

MTRM-150B

G650

DN150

920

808

362

337

532

406

432

285

240

8

M20×65

MTRM-200A

G1000

DN200

1020

908

412

387

532

406

432

340

295

12

M20×75

- 1: strictly prohibit the flow meter on-line welding pipe flange.

2: Before and after installation of flowmeter, the pipeline should be purged, and the impurities such as welding slag, iron scraps and sand in the pipeline should be thoroughly removed (special attention should be paid to removing impurities in the elbow of flowmeter before vertical installation), so as to avoid foreign matter entering and damaging the flowmeter, and the inner wall of the pipeline should be clean and free of fouling.

3: In order to facilitate regular maintenance and weekly inspection of flowmeters, it is recommended to set up bypass pipelines (the bypass pipeline valves should be locked in normal operation).

4: before installing the meter, check whether the rotor is flexible.

5: Seals should not be protruded into the pipeline during installation. There is no deviation between the inlet and outlet axes of the flowmeter and the connecting pipeline.

6: When the flowmeter is installed horizontally, it is recommended to install a steel expander (compensator) after the flowmeter. The expander must meet the requirements of nominal diameter and nominal pressure of pipeline design. The telescopic device is used to compensate for the stress of the pipeline and facilitate the installation and disassembly of the flowmeter.

7: After installation, air tightness test should be carried out on the pipeline to strictly check the air tightness of the pipeline. For auxiliary technical equipment equipped with pressure compensator, attention should be paid to the pressure range of the pressure testing equipment in order to avoid damaging the pressure measuring components.

8: When installing the flowmeter, we should pay attention to the flow direction of the flowmeter is consistent with the flow direction of the gas, and strictly examine the use conditions and installation environment conditions of the flowmeter.

9: there is no strong external magnetic field disturbance and strong mechanical vibration around the flowmeter.

10: the flowmeter with volume correction device must be reliably grounded, but it must not be shared with the strong power system ground wire.

11: there should be no corrosive gas to the aluminum alloy at the installation site.

12: When additional power supply is needed, it must be in accordance with the requirements of the corrector, otherwise it will damage the instrument or cause safety problems.

13: After the flowmeter has been installed correctly, before entering the normal operation, the corresponding type of lubricant should be added to the flowmeter according to the requirements, and the quality and quantity of oil should be checked regularly during the operation. Replace and replenish lubricating oil in time to ensure the normal operation of the flowmeter.

14: The valve before and after flowmeter should be opened and closed slowly during operation, so as to avoid sudden change of instantaneous flow rate and damage flowmeter.

15: The operation of upstream gas filters should be checked regularly during operation, and the filter elements should be cleaned or replaced when necessary.

16: In order to ensure the normal use of flowmeters, attention should be paid to and prevention of overpressure and overflow of flowmeters during operation.

- Index >

- Product Center >

- MTRM Series Roots flowmeter >

Product Center