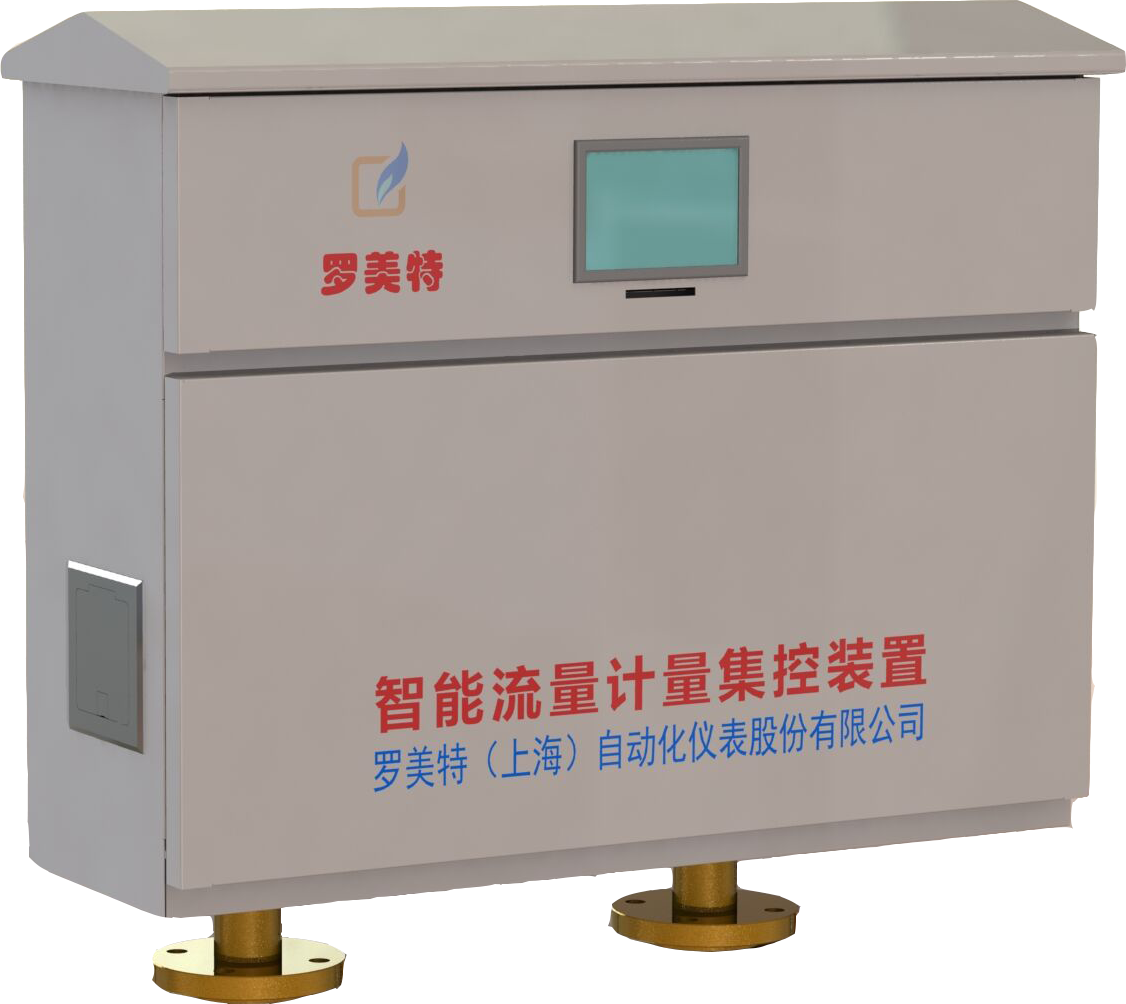

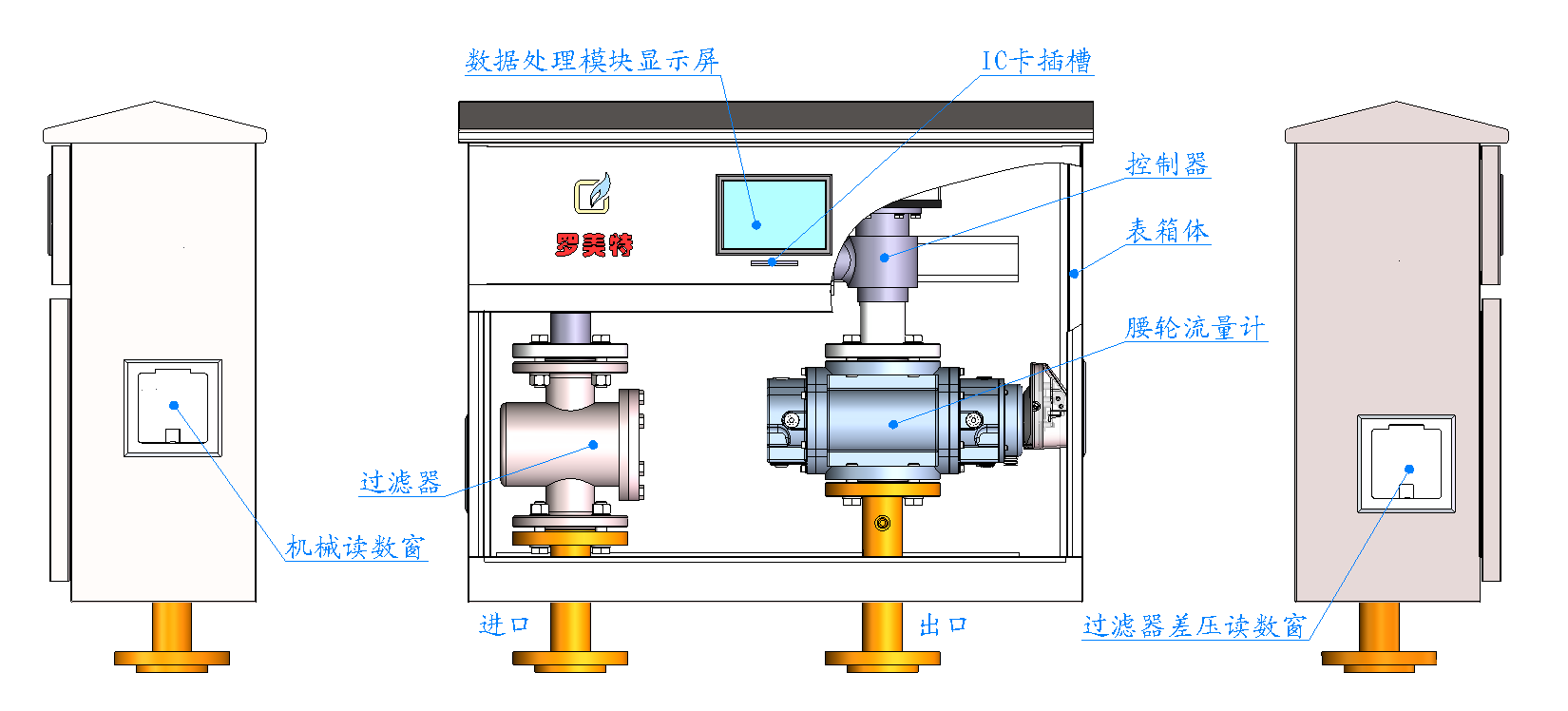

- Intelligent flow metering centralized control box is a complete set of metering equipment, which directly assembles lumbar wheel flowmeter, remote RTU, filter, IC card controller, pipeline, flange and other equipment and components in the customized box. It has high measuring accuracy, wide measuring range, strong anti-interference ability, convenient installation and maintenance, long service life, and intellectualized management. It is an ideal flow metering device for domestic and foreign urban gas, Gongfu users, oil field chemical industry, industrial boilers and other departments.

- 1: Flowmeter has high strength surface treatment, strong stress resistance, no contact rotation, good oil lubrication, and avoids lumbar wheel jamming. The normal running period is as long as 20 years.

2: has a wide range and a maximum 1:300.

3: has high accuracy and high reliability. The accuracy of base meter is 1.

4: starts with a minimum flow rate of 0.02m3/h.

The maximum pressure loss of 5: is between 0.1kPa and 0.78kPa.

6: products with different specifications are exchanged for more parts and reduce inventory rationally.

The 7: bearing and the waist wheel are embedded in the high pressure seamless one step to ensure the long-term rotation of the waist wheel.

8: the size of the waist wheel and shell is designed by golden section to ensure the optimal rotation state.

9: mechanical counters need no maintenance and long service life.

10: can realize prepayment and automatic charging function.

11: accessories features

12: counter - permanent lubrication performance, long service life, no need for maintenance.

13:The external ports of PCB are all designed with photoelectric isolation to ensure the normal operation of the volume corrector all the time.

14: Multi-specification pulse output mode and 485 communication mode can meet the needs of user IC card, remote transmission and other functions.

15: low flow compensation function, to ensure accurate measurement of parts below 10%FS traffic.

16: intelligent volume correction instrument has strong anti-interference ability and high reliability. Remote transmission function, real-time communication, immediate alarm.

17: adopts intelligent anti-theft combined with traditional anti-theft mode, which can effectively prevent illegal gas stealing.

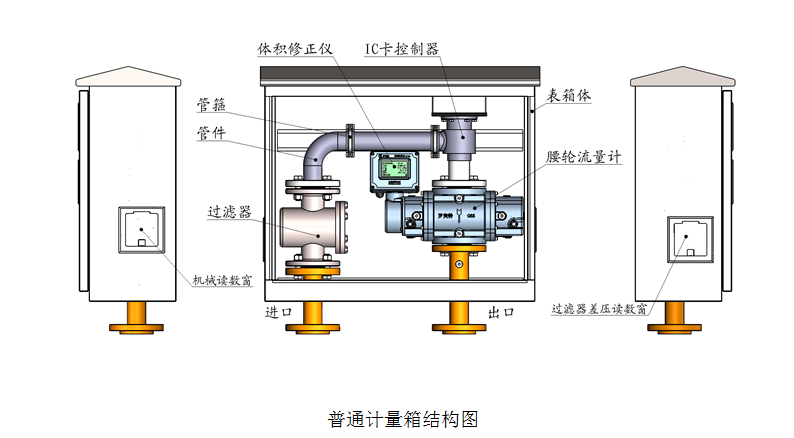

18: The inverted U-shaped pipe fittings are used to connect the filter and flowmeter in the box, which can minimize the pressure loss of the pipeline and avoid the sticking of the meter caused by the large particle impurities falling into the flowmeter with the airflow. The inner part of the pipe is treated with rust prevention to prevent the pipe from rusting for too long and the iron slag falling into the flowmeter and causing the meter to jam.

产品名称

规格型号

L1

L2

L3

H

h

D

d

普通计量箱

G10-X

855

825

448

720

100

320

296

普通计量箱

G16-X

855

825

448

720

100

320

296

普通计量箱

G25-X

855

825

448

720

100

320

296

普通计量箱

G40-X

855

825

448

720

100

320

296

普通计量箱

G65-X

855

825

448

720

100

320

296

普通计量箱

G100-X

950

920

465

750

100

320

296

智能流量计量集控箱结构图图

产品名称

规格型号

L1

L2

L3

H

h

D

d

智能流量计量集控箱

G10-XK

855

825

448

720

100

320

296

智能流量计量集控箱

G16-XK

855

825

448

720

100

320

296

智能流量计量集控箱

G25-XK

855

825

448

720

100

320

296

智能流量计量集控箱

G40-XK

855

825

448

720

100

320

296

智能流量计量集控箱

G65-XK

855

825

448

720

100

320

296

智能流量计量集控箱

G100-XK

950

920

465

750

100

320

296

- 1: The inside of newly installed pipes should be cleaned up to prevent iron slag, welding slag and other impurities from blocking filters and affecting the normal use of metering boxes.

2: The metering box should be installed in places which are easy to maintain, free from strong electromagnetic interference, mechanical vibration and thermal radiation.

After the 3: metering box is installed, leak detection should be carried out to ensure the safe construction.

4: strictly prohibit welding line flange on metering box.

The flowmeter with 5: volume correction device must be reliably grounded, but it must not be shared with the ground wire of the strong power system.

There should be no corrosive gas on the 6: installation site.

7: When additional power supply is needed, it must be in accordance with the requirements of the correcting instrument, otherwise it will damage the instrument or cause safety problems.

8: to damage pipelines and instruments in order to prevent instantaneous air impact, the following procedures shall be applied.

L close the valve before and after the metering box, slowly open the front valve, so that the gas is filled with the flow chamber.

L bypass valve is first opened through bypass pipe.

L slowly opens the valve behind the metering box to operate at a low flow rate and observe whether the operation is normal.

After the L metering box is running, the bypass valve is closed, and the valve behind the flowmeter is adjusted to the required angle.

L valve should be slowly closed after closing the valve, do not suddenly shut down.

9: The operation of upstream gas filters should be checked regularly during operation, and the filter elements should be cleaned or replaced when necessary.

10: In order to ensure the normal use of flowmeters, attention should be paid to and prevention of overpressure and overflow of flowmeters during operation.

11: installation and use requirements of intrinsically safe explosion-proof products

L The intrinsic safety explosion-proof products equipped with SMARC volume corrector must comply with the following requirements in addition to the seven precautions mentioned above.

L field installation and maintenance must turn off external power before opening.

The L product shell has earthing terminals, and users should be reliably grounded when using products.

There should be no harmful gas on the L installation site for corrosion of aluminum alloy.

Maintenance and battery replacement must be carried out in a safe place. Maintenance can only be carried out when the presence of non-flammable gases is confirmed at the installation site.

When using external power supply, it must be matched with the related equipment (safety grille) identified by the explosion-proof certification authority to form the intrinsic safety explosion-proof system before it can be used in the corresponding explosive dangerous places. The shielded cable is used to connect the cable, and the shielding layer is grounded in a safe place. The distribution parameters of the cable are controlled within 0.05 uF/1mH.

Safety grids shall be installed in safe places, and the installation, use and maintenance of safety grids shall comply with the relevant provisions of the safety grids operating instructions.

L users are not allowed to change electrical components in their own products at will.

When installing, using and maintaining products, users must abide by the relevant provisions of GB50058-92 "Code for Design of Electric Power Devices in Explosive and Fire Hazardous Environment" and "Code for Electrical Safety in Explosive Hazardous Places of the People's Republic of China".

L intrinsically safe type of hazardous area below 1 zone for combustible gases of type II B class T4.

- Index >

- Product Center >

- Metering box >

Product Center